Router Bit Profiles Every Woodworker Should Know

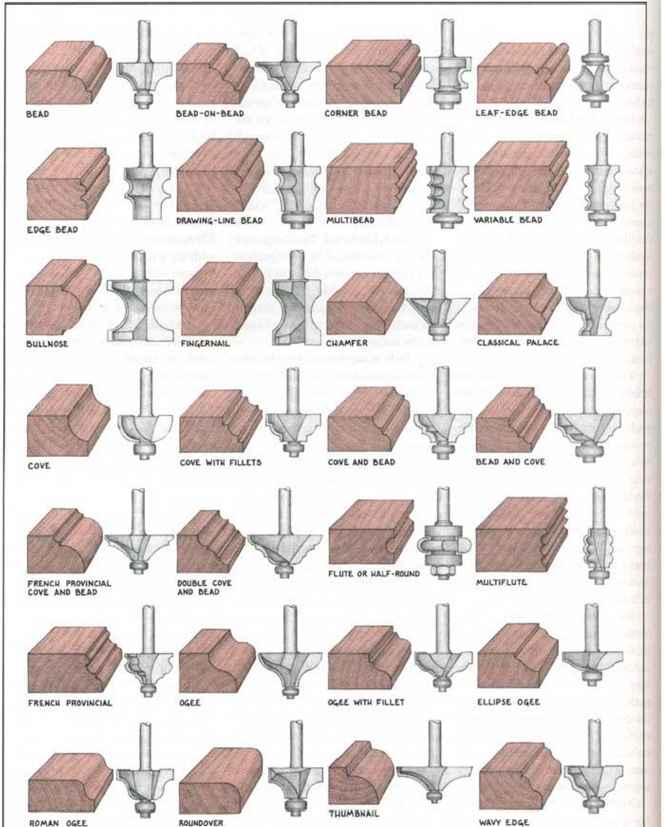

In routing decorative treatments, the tricks are less in the doing, and more in the planning and bit selection. There arc a great many decorative profile bits available, and in many cases, even most cases, you can make a single pass with a bit to create the embellishment your project requires.

Once in a while, though, you need to make passes with two or more cutters to get the contour you want. You need to choosc these cutters carefully. plan the order of cuts, and determine how you're going to suppon either the router or the work.

There are a few tricks here, but mostly it's straightforward routing. You simply must choosc the cutters wisely.

Almost all decorative profiles can be traced to some basic molding shapes. You may have come across these mosdy Latin terms, found diem hard to connect to your woodworking. and so pretty much forgot diem. But let's take a shot at connecting them to today's router bit catalog and

molding forms. I think you'll see them in the bit profiles shown and described beginning on the next page.

Scotia: A concave profile, it is greater than a quarter round. To rout a scotia. use a core-box bit to cut an arc like the one shown, or, if it is greater than 180 degrees, a radius bit.

Cavetto: This is a large, concave quarter round—a cove, in other words. So use a cove bit.

In analyzing the profile you want to cut, lay the bits themselves on the layout and line them up with the profile. This will help you determine which bits to use, how to orient the work for making the cuts, and in what order the cuts have to be made.

THE BASIC MOLDING FORMS

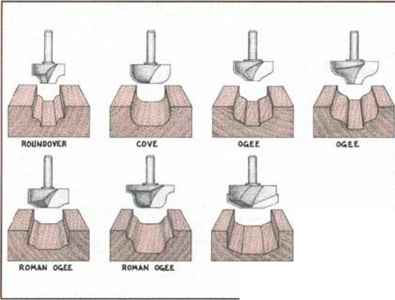

Ogee (or cyma reversa): This one we know. It's an S-shapcd curve, with a convex form at the top, fairing down into a concave one. Strictly speaking, to be an ogee, the profile should have a flat. narrow step, known to architects as a listel and to the rest of us as a fillet. This fillet is at the top, ending the concave curve. You know what bit to use to form this shape.

Reverse ogee (or cyma recta): This corresponds to the Roman ogee, which is the name of the bit you'd use to cut one. It starts at the top as a concave curve, flowing down into a convex one. I'm not sure where the term Roman, as used in Roman ogee, came from. What distinguishes Roman moldings is that they were based on the circle (the Greeks based their molding forms on the ellipse). We trace the molding forms we use today back to those classical Greeks and Romans.

Astragal: A small, convex half round, the astragal conesponds to what bit makers call a full bead. In current usage, an astragal is usually a separate molding strip. To form an astragal in the strict sense requires an edge-beading bit. Making an astragal strip can be done with a bull-nose, beading, or round-over bit.

Tonts: A large, convex half round, the torus is an astragal on steroids. A bull-nose bit forms a torus.

Ovolo: A convex quaner round between fillets, an ovolo is what is usually called a bead these days. Cut it with a beading bit.

Fillet: Previous definitions have already conveyed what a fillet is. It's a small, fiat section used to separate other profiles. It can be a square-sectioned strip across a fiat, but it's often used as a step between profiles or at the ends of a profile.

Now let's take a look at the range of decorative bits that are on the market. You'll sec the connections to the basic molding forms. You may also begin to see how the multiple-form bits—like cove-and-bead bits, for example—combine the basic forms.

As you study the bits, you'll see that you can usually cut a cove-and-bead profile with a cove bit and a round-over bit, for example. The advantage of using a bit that combines both shapes on a single cutter is that you'll save setup and cutting time. The disadvantage is that these multiple-profile hits tend to blind us to our many options. If you arc like me, you tend to "see" in single-bit terms. Until 1 worked with Fred on this chaptcr. I'd look for a single bit that would cut the specific profile 1 had in mind, rather than focusing on how I could produce it with the few fundamental bits.

I hope this article will serve as a jumping-off point for you—as it has for me—in developing your own special patterns, or simply in using the basic bits you have to produce more complex combinations.

I've collected the bits into two categories: edge-forming bits and groove-forming bits. This is by no means exhaustive; it leaves out quite a few decorative bits, as well as all those that are utilitarian. I pored over catalogs from eight bit vendors, trying to compare bits according to their forms, not the names the manufacturers gave them. Of course, there arc more than eight companies making or importing and marketing router bits, but I think the eight lines are representative of what you'll find on the market. (See "Sources" on page 337 for these companies' addresses and phone numbers.)

Edge-Forming Bits

These bits shape the edges of boards, forming one of or combinations of the eight basic molding shapes.

In general, edge-forming bits are characterized by the presence of a pilot on the end of the bit. The pilot catches on the edge of the work and prevents the bit from setting out across the face of a board, forming a groove in the process. With a piloted bit. setup is pretty much limited to establishing the bit height. The width of the cut is governed by the pilot. You can switch to a different bearing size or work with a fence or edge guide to change the cut's width.

Beading: Produces a quarter round with one or two fillets. The width of one fillet is governed by the diameter of the pilot bearing, while the width of the other is governed by the depth of cut. A beading bit can be transformed into a round-over bit by changing the bearing (and vice versa). Bead radii range in steps from Mftinch to 1 inch: their vertical depth of cut, from inch to IKh inches. Metric sizes are available from Byrom.

Bead-on-bcad: This unusual profile is available only from Amana (as a classical molding bit) and MLCS (as a multibead bit). It seems to be a kin of the cove-and-bead. but with a two-tier quarter-round profile. Depending upon the pilot bearing used and the dcpth-of-cut setting, you can produce a profile with one or two fillets. Each source has two sizes listed.

Corner-beading: I hree slightly different profiles can be cut using this bit. depending upon the depth of cut and the number of passes. In a single pass, you can cut a couple of different edge beads; with two passes.

Leaf-edge-beading: Forms a round-edged groove near the edge of the workpiecc. Making a pass in adjoining faces of the workpiece will yield an ellipsoid comer bead, hence the leaf-edge moniker. If you make a pass with a round-over bit in conjunction with the leaf-edge-bcading bit. you'll get a round edge or comer bead. All of these bits have two pilot bearings, one on the shank above the cutter, one on the tip below the cutter.

Edge-beading: Since this bit lacks a pilot, it has to be used in conjunction with a fence or edge guide. Although it yields a profile very similar to the comer-beading bit's, it has a roundover and a tad more extension below the bead.

Drawing-line-bcading: This bit closely resembles the edge-beading bit Compare the profiles, however, and you'll see that this one arches away from the bead, rather than producing a pronounced fillet or fiat. The depth-of-cut setting determines whether or not you get a fillet above the bead.

Multibead: The baseline bit in this category—available from Byrom, Amana, MLCS, and Eagle America.

Variable-bead: This bit resembles the multibead bit. but each of the beads it cuts is a different radius. Byrom's bit is piloted. Amana's is not.

Bull-nose: A sort of big brother to the beading bits, the bull-nose bit is used to shape the full edge of a board. The "nose diameter" reflects the thickness of stock that can be nosed, i.e., given a full 180-degree roundover. Byrom refers to this bit as being "full radius." The bits have flats above and below the half round, which will create fillets on stock that's thicker than the nose diameter. In general, these bits do not have pilots. The bearings match the smallest diameter of the cutter. In use, the bearing rides against a template clamped or tacked to the workpiece, rather than against the workpiece itself.

Fingernail: Like the bull-nose bit. this bit shapes the edges of boards. It is an unpiloted bit. It has shon flats above and below the cutter arc, which will produce fillets on stock that matches the cutter height. Unlike the bull-nose, it cuts a shallow arc— the fingernail shape—rather than a full 180-degree roundover. (The same effect can be produced on thin stock by using a large-diameter bull-nose bit.) The size of the bit is usually expressed in terms of the straight-line length of the arc. rather than the radius of it.

Chamfer: In the small sizes, this bit puts a decorative chamfer on work. In larger sizes, it can bevel dimensional stock (that is. cut a chamfer that extends through the full thickness of the stock). Every manufacturer has at least one 45-degree bit.

Classical palace: Among the many bits labeled "classical," this style is generally used to shape the full edge of a board. Since it doesn't include a pilot, stock must be guided with a fence. It cuts a cove with a full bead. Cutting lengths range from Ya inch to 1Y* inches; bead diameters, from Y* inch to Mb inch; and total relief, from V* inch to Yi inch.

Cove: As its name implies, this bit cuts a cove in the edge of a board. The cove is one of the basic building blocks for many molding profiles. When used in conjunction with beads and fillets, an almost infinite variety of shapes is possible.

Cove-with-fillets: This bit is available with either one or two fillets. It is another of the "classical" profiles and finds use in making period moldings. Variations of the profile are possible by using different sizes of pilot bearings.

Covc-and-bead: A bit that goes by lots of names—classical, ogee-and-step, classical ogee, classical bold covc-and-bead, as well as cove-and-bead. (Bit marketeers just love that term "classical.") To mc, the characteristic of all these bits is that they combine a cove and a bead separated by a fillet or step. Both covc and bead have the same radius. The bead comes off the pilot.

Bead-and-cove: This profile is the reverse of the covc-and-bead. though you wouldn't be able to tell that from the bit makers' descriptions of it. (Most catalogs will identify two or three different profiles as "classical" and let you distinguish between them as you will.) As with the cove-and-bead, the bead-and-cove combines the two basic forms, separating them with a fillet. Both cove and bead have the same radius. Here the covc comes off the pilot.

French Provincial cove-and-bead: The distinction between this bit and the regular cove-and-bead is that the bead has a markedly larger radius than the cove. It's a very graceful profile for finishing the edge of a tabletop. I found it only in the Byrom, MLCS, and Eagle America catalogs.

Double cove-and-bead: A Cascade exclusive is this more complex version of the covc-and-bead bit—two coves separated by a bead with fillets. The radii of the forms appear to be the same.

Flute or half-round: This bit cuts a flute—a rounded groove—at right angles to the bit axis, and it's sometimes referred to as the reverse of the bull-nose bit. It's useful for fluting a narrow edge, which wouldn't provide good footing for a router that's set up with a core-box or roundnose bit. The flute depth is controlled by the pilot bearing, the position by the router's bit-hciglu setting. The distinction between flute and half round lies in the width of the cut.

Multiflute: Multiple flutes arc often found on the legs of Chippendale chairs and tables. This bit curs three closely spaced flutes in a single pass.

French Provincial: As with some of the other bits shown here, the name the marketeers apply conveys nothing about its profile. A big chunk of steel, this 1 V-»-inch-diamctcr bit cuts a profile combining the covc and bead with a full bead. The quarter-round bead comes off the bearing, and the full bead is at the shank end of the cuttr.

Ogee: This S-shaped curve is convex at the top and fairs down into a concave one. What's confusing is that most bit catalogs display the profile upside down. The bit is usually portrayed in a shank-up, pilot-down attitude, and the resulting cut is an upside-down ogee. The easiest way to identify the ogee bit is to check the curve at the pilot bearing; the ogee bit has a confin e curve there. In most designs, the radii of both the convex and the concave curves are the same. And though the ogees don't cut a fillet, you can change to a smaller-diameter pilot bearing and get one.

Ogee-with-fillet: This ogee pattern has a step at the end of the concave portion of the curve. A step can be produced at the other end of the profile by switching pilot bearings.

Ellipse ogee: The Roman ogee was based on the circle, but the Greeks based their ogee on the ellipse. The ellipse-based profile is found only in the Eagle America and Cascade catalogs.

Roman ogee: This is the reverse of the ogee; it isn't an upside-down ogee. The curve starts at the top as a concave, and fairs down into a convex curve. As with the ogee, bit catalogs can cause some confusion because they present the cut profile upside down. The easiest way to avoid the confusion is to remember that the Roman ogee bit has a convex curve coming off the bearing. In most bits, the radii of both the concave and convex curves are the same.

Round-over: This bit is THE basic edge-forming bit. It goes by four different names: round-over, rounding-ovcr. corner-round, and quarter-round. Very simply, it rounds an edge to a given radius. The bit can be used to nose an edge: Make a cut, turn the board over, and make a second pass. The bit has a shoulder, so that at full extension, it will form a fillet. If a smaller pilot bearing is used, a second shoulder can be produced, in effect making the bit a beading bit. It is available from tvery bit maker in a variety of sizes.

Thumbnail: The purpose of this bit is shaping the edges of tablctops. In most patterns, the cutter is a round-over based on an ellipse rather than a circle. Like a round-over, the cutter has a shoulder that will produce a fillet (in some cases, a slightly beveled fillet) if the bit is extended enough. A smaller pilot bearing will yield a second fillet. Freud and Eagle America have related patterns that add a bead. cove, or ogee to the profile.

Wavy-edge: This bit produces exactly what the name says, a wavy edge. It's an undulating curve with two convex forms flanking a concave form. All the radii are equal. A shoulder on the cutter can fonn a fillet, depending upon the depth-of-cut setting.

Groove-Forming Bits

Unfettered by pilots, the groove-forming profile bits are usually more versatile and flexible in routing trims and moldings. The t ruth is. the pilot is often a hindrance.

For example, suppose you want to crcatc a cove-and-bead profile of your own proportion on a board's edge. You rout the bead right along the board's edge with a beading or round-over bit. Now you are ready to nestle the cove in next to it. But the covc bit's pilot won't let you position the covc wherever you want. In this situation, the pilot is an impediment.

You need a groove-forming bit, i which doesn't have a pilot. You control the bit using a fence or an edge guide or a template. The bit forms a [ groove with a profile.

The variety of groove-forming profile cutters is limited. Here are the main ones.

Beading: Is this a trick name? you ask. Because of their names, it is easy to confuse this groove-forming beading bit with the edge-forming bit described earlier. There are similarities beyond the names. This bit forms quarter-round profiles as it grooves, one on each side of a flat. By making repeated passes, you can form full beads. The typical beading bit makes a cut Y* inches wide, including two '/^-inch-radius quarter rounds. Cascade sells several largcr-diamcicr bits, the biggest of which forms a 1-inch-widc groove with two 'A-inch-radius quarter rounds. The scale of the beading profile distinguishes it from the groove-forming or "plunge" round-over bit, which begins where i the beading bit leaves off. Used with a fence or guide, the beading bit can be used as an edge former.

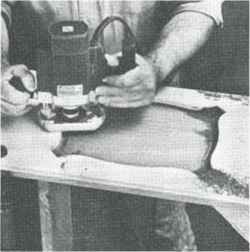

Many of the almost miniature profile-grooving bits— the classical, traditional, leading, and veining—arc intended for routing decorative lines. Here a flat door panel is being embellished with such a cut.

Classical: This bit name doesn't throw any light on the nature or profile of the bit, but that's the way marketing works, isn't it? We respond to the name emotionally rather than rationally. What this is—rationally speaking—is the groove-cutting form of the cove-and-bcad bit. You use it to form round-bottomed, bead-sided grooves and to embellish the inner walls of wide recesses with that cove-and-bcad profile. The typical "classical bit" forms a round bottom, but a couple of bit makers have flat-bottomed versions of this bit. Bosch and Amana call the latter form a "traditional" profile. Freud and Byrom also have versions with a square step between the cove and the bead. The radii of the beads range from Va inch up to Y* inch, with cutting widths ranging from Vi inch up to 1 Vi inches.

Core-box: A primary bit forddecorative work is the core-box. Over' bit maker has the core-box profile, and nearly every basic bit set includes acorc-box (or roundnose bit, as some forms of it are called). But it's very easy to overlook the core-box's utility in decorative work, probably because the "set bit" is pretty small. The core-box is a cove bit without the pilot, so it can be used not only for fluting but for cove cuts as well. Quite often in decorative work, a pilot bearing gets in the way when you want to place one form right next to another. These arc the situations in which you reach for the core-box. Usually, the core-box is a hemisphere-shaped cutter, but when the cutting edges arc extended, the bit is known as a roundnose. The bit sia: is usually expressed in terms of the diameter.

Ogee: The ogee is one of the basic molding shapes. The groove-forming versions arc pretty tiny. The typical bit cuts a groove with a fiat bottom.

Plunge round-over: This is another essential bit for decorative work. It's the groove-forming version of the familiar round-over bit. There seem to be two forms of this bit. The typical one cuts a fiat between two quarter-round forms. The cutting edges of this style bit aren't strictly quarter-round, since they have straight extensions from the radiused section. As a consequence, there's a flat between the roundover and the groove bottom. The flat varies from Ys inch up to Ys inch long, depending upon the radius of the roundover. The second style is called point-cutting by its manufacturer (Eagle America). This bit produces two quarter-round forms that converge in a V-groove rather than a flat. There's no fiat spot below the roundover with this bit, which can be a valuable characteristic.

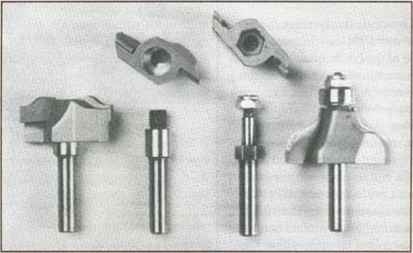

Paso Robles Carbide will turn any of its independent cutters into a groove-cutting bit. The standard cutter (top right) has a hex socket to fit over a matching section of the arbor. These cutters will Jit on arbors with and without pilots (right and right ccnter). To eliminate any projection beyond the cutter, a special threaded arbor is used (left center). The hex is machined out of the cutter body (top left) and the hole for the spindle is threaded for the arbor. The resulting bit (left) may be somewhat less convenient to use for edge treatments than one with a pilot, but it can be u sed easily for more operations than a comparable piloted bit.

Paso Robles Carbide will turn any of its independent cutters into a groove-cutting bit. The standard cutter (top right) has a hex socket to fit over a matching section of the arbor. These cutters will Jit on arbors with and without pilots (right and right ccnter). To eliminate any projection beyond the cutter, a special threaded arbor is used (left center). The hex is machined out of the cutter body (top left) and the hole for the spindle is threaded for the arbor. The resulting bit (left) may be somewhat less convenient to use for edge treatments than one with a pilot, but it can be u sed easily for more operations than a comparable piloted bit.

As you peruse the available pro-Pile bits, you may feel a pang of regret that you can't get the same profile assortment in the groove-forming style of bit that you can in the edge-forming style. You'd like to get a Roman ogee or a cove-and-bead shape at a spot an inch or two from the edge of a board, and there's no groove-forming bit available that'll do it.

Well, now you can buy pilot-free edge-formers. Paso Robles Carbide makes and sells a line of assembled bits featuring interchangeable cutlers. You save money by buying one arbor and individual cutters. Switching from one profile to another is a matter of changing the cutter on the arbor.

In the standard Paso Robles system, the cutter fits over a spindle on the arbor, and a locknut keeps the cutter and pilot bearing in place. To prevent the cutter from spinning independent of the arbor, a hex socket in the cutter fits over a matching section on the arbor. You can eliminate the pilot bearing using a special arbor, but it still has that locknut protruding from the cutter's tip.

Paso Robles now has worked out a way to mount the cutters on a threaded shank. To eliminate any protrusion from the cutter tip. the hex socket is machined out. forming a round countcrbore. and the hole for the spindle is threaded counter to the direction of bit rotation. The arbor used is a shank with a threaded section at the tip. Tum the arbor into the cutter, and the bit's ready for use.

Any Paso Robles interchangeable cutter can be customized in this way. Once it is, of course, it can't be used with the standard arbors because the hex socket is missing. And because the cutting edges don't extend all the way across the end of the cutter, it can't be plunged. You have to plow in from an edge or sweep in to start a groove. These arc minor impediments.

The result is that you can cut the profile just where you want it—on an edge, fractionally in from the edge, or right smack in the middle of the board.

Radius; Looking like a ball on the flagpole, the radius bit—sometimes called an internal bull-nose— forms round grooves. In section, the groove's arc can exceed 180 degrees. While it is usually relegated to cutting drawer pulls, it can be useful for cutting coves in tight quarters.

Veining: Of limited use is the veining bit. It cuts a narrow groove— Vs to 'A inch wide—usually with a rounded or V-shaped bottom. Typically, it's used to rout decorative veins in panels.

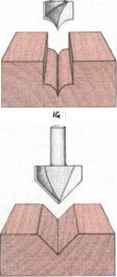

V-groove: This is the groove-forming equivalent of the chamfcr bit. Standard V-groove bits are 90 degree, meaning the cutting edges arc earned 45 degrees from the bit axis. Also available, however, arc 60-dcgrec bits. In addition, a flat-bottomed V-groove bit is made especially for routing outdoor signs; the theory is that flat-bottomed grooves will shed water better than V-grooves.

Continue reading here: What Pilot

Was this article helpful?

Responses

-

amanuel5 years ago

- Reply

-

ilkka6 years ago

- Reply

.jpg)